Industrial 3D Scanning for Mechanical Parts in Brisbane

High-accuracy structured light 3D scanning for maintenance, engineering, and manufacturing – with part accuracy up to ±0.04 mm. We deliver CAD-ready STEP files for mechanical and industrial components. Architectural or building scanning is outside the scope of this service.

Submit your project online

Submit your part details and upload photos, drawings, or dimensions.

We’ll review and provide an accurate quote-fast and reliable.

Brisbane 3D Scanning

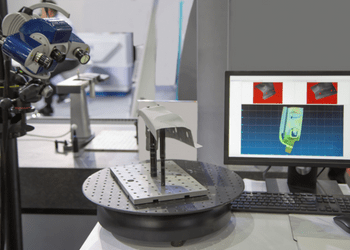

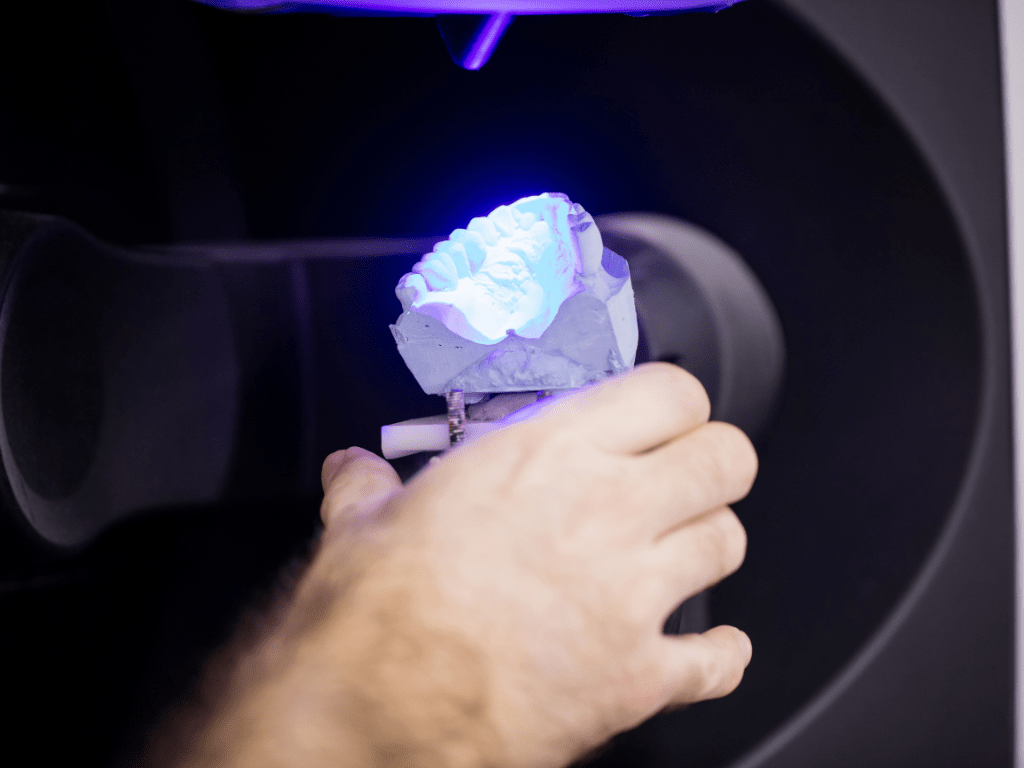

High-accuracy structured light 3D scanning captures complex mechanical geometry quickly — data that would take days or weeks to measure manually.

Precision & Metrology

Our structured light scanner delivers measurement accuracy of up to ±0.04 mm with high resolution point capture suitable for CAD modelling, inspection, and reverse engineering workflows.

Fast, Industrial-Focused Scanning

Professional structured light scanning tailored to engineering & manufacturing.

Advanced Equipment & Skilled Operators

We use precision metrology tools, not consumer scanners.

Responsive Service for Industrial Clients

We prioritise reliability, accuracy and clarity in every project.

3D Scanning for industrial design and manufacturing

Industrial parts with complex geometry used to take days or weeks to model manually.

With professional 3D scanning, we capture precise surface data in hours.

Scan data is processed into clean digital formats that can be used for CAD modelling, reverse engineering, redesign, inspection, or export to CAM software for production.

Watch your technology evolve as you visualize and test new ideas.

Create high resolution scans with Mad Max Engineering 3D Scanning.

3D Scanning

The most modern technology accompanied by over 25 years of engineering and scanning experience.

We Come To You

On-site scanning available for large, heavy, or immobile industrial parts.

We bring the metrology-grade scanner to your workshop or facility when needed.

Fast Turnaround

We prioritise rapid data capture and processing so you can get actionable CAD results quickly and keep your project moving.

Brisbane's #1 Scanning firm

We understand what engineers and manufacturers need: precision, clarity, and practical deliverables.

Our structured light scanning service is tailored for industrial parts and engineered components.

Advantages Of MMES

Our scanning service delivers:

• High precision and repeatability for engineered components

• Data suitable for CAD, reverse engineering, and production

• Scanning of complex geometry with measured accuracy

• A structured and reliable workflow for industrial clients

Scalability and repeatability.

Cost effective.

Speed and precision.

Locally owned and operated.

Why Scan Your

Products & Projects?

Industrial uses of 3D scanning include:

Improve part design and engineering accuracy

Capture precise dimensions for prototypes or production parts

Reverse engineer components where drawings are unavailable

Recreate manufacturing data for obsolete or undocumented parts

Detect faults and verify critical geometry

Support inspection, simulation, and quality control processes

Prepare data for CNC machining or additive manufacturing

Improve your product

Bring your components into modern digital workflows.

Our scanning service delivers precise part data that supports fault detection, functional improvements, and reduced production risk.

What Is industrial 3D Scanning?

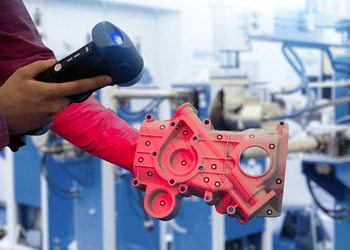

Industrial 3D scanning uses structured light technology to precisely capture surface geometry of mechanical parts and engineered components.

Data from the scanner is processed into accurate digital representations that can be used for CAD modelling, reverse engineering, inspection, manufacturing and production preparation.

Applications of Industrial 3D Scanning

Our 3D scanning service is focused on practical engineering and manufacturing outcomes.

We capture accurate geometry from mechanical and industrial components so they can be

recreated, repaired, modified, or manufactured with confidence.

Common applications include:

Reverse Engineering Services

Reverse engineering worn or obsolete parts where drawings no longer exist

Recreating legacy components for continued production

Capturing complex geometry for CAD modelling and redesign

Preparing STEP data for CNC machining or additive manufacturing

Dimensional verification and comparison against existing CAD

Engineering analysis, fitment checks, and design improvement

Our focus is delivering usable engineering data for real industrial workflows — not consumer scanning, architectural models, or entertainment applications.

Frequently Asked Questions

What accuracy can you achieve?

We use structured light 3D scanning with measurement accuracy up to ±0.04 mm on suitable part sizes.

Final accuracy depends on part size, geometry, surface condition, and required tolerances. All scan data is verified and rebuilt into CAD before STEP delivery to ensure engineering-grade results.

What types of parts do you scan?

We scan mechanical and industrial components only. This includes parts such as brackets,housings, shafts, assemblies, fixtures, and other engineered components used in manufacturing, maintenance, and machinery.

Do you scan buildings, rooms, or architectural features?

No. We do not provide architectural, building, room, or scenery scanning. Our service is strictly focused on mechanical and industrial components.

What file formats do you deliver?

Our primary deliverable is CAD-ready STEP (.step / .stp) files. Depending on the project, we can also supply surface or solid CAD models suitable for reverse engineering and manufacturing.

Can you reverse engineer parts with no drawings?

Yes. A common use case is recreating parts where no CAD files or drawings exist. We scan the physical component and generate accurate CAD data for replacement, modification, or production.

How large or heavy can the parts be?

We can scan small components as well as large or heavy parts. For components that cannot be moved, we offer on-site scanning within Brisbane and surrounding areas.

Do you offer CNC machining or 3D printing from scanned parts?

Yes. If required, we can continue from scan data through reverse engineering into CNC machining or 3D printing for prototypes or production parts.

How do I get a quote?

Upload clear photos, drawings, or existing documentation using the form on this page. Including approximate dimensions, weight, and intended use helps us provide an accurate quote quickly.