CNC MACHINING Brisbane

MMES offers a 4 Axis precision CNC milling services for rapid prototyping and production parts. We are CNC milling experts and offer the fastest turnaround times in the industry.

Submit your files direct online

- Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, DWG, PDF, STL, OBJ, 3MF) directly to get a lightning-fast quote on your project.

- Our team will be in touch within 48 hours.

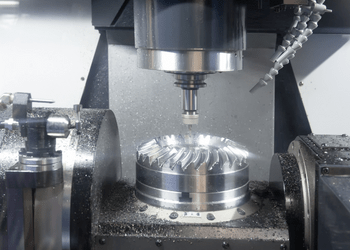

Brisbane CNC Milling

Fast, Convenient & Affordable

Modern Tools & Technology

A Team Who Cares

Efficient, cost effective production runs

If you’re looking for cost-effective production runs or a fresh start for your manufacturing processes, we can help you get there. We’ve manufactured our own successful products, so we understand the challenges of producing locally and competing globally. Whether you’re a large company looking to have your new parts produced or an entrepreneur looking for your first production run, we will share the excitement and would take pride in helping you accomplish your goal and exceed your expectations.

We are constantly exploring and investing in the latest and greatest work holding and tooling to keep the cycle times to a minimum, keeping the cost down for ourselves and our customers without sacrificing quality.

We know businesses operating in our local market have small to medium production scale requirements with flexible lead times and we have proven systems in place ready to meet our customer needs. Pallet changers and other quick change fixtures for reduced setup time and maximum throughput.

Our mission is to help you succeed by providing high-quality production scale CNC milling that won’t break your bank account! Don’t wait on expensive and slow shipping from China for poor quality parts—let us show you how easy it is to have them manufactured in Brisbane and let’s keep Aussie dollars and jobs in Australia, where they belong !

CNC ENgineering solutions that cater to every project

Simplified project completion for maximum efficiency and quality at reduced cost.

CNC Milling Service

A subtractive manufacturing process that involves cutting down a solid block of desired material into final prat or prototype.

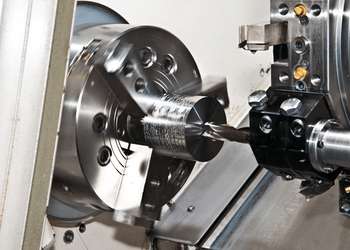

CNC Turning Service

Just as the name suggest, the process involves turning of workpiece at high rotations and combines a lathe with milling.

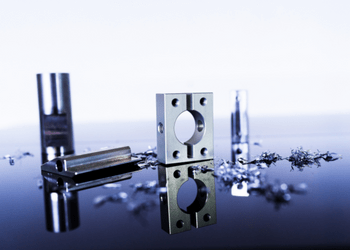

CNC Materials

We work with a wide range of materials. Aluminium, Brass, Copper, Stainless Steel, Steel, Acetal, Delrin and other plastics.

Brisbane's #1 CNC Engineering firm

We’re a revolutionary machining company that understands what’s important to engineers and manufacturers of prototypes. We’re here to give you the convenience of accessible machining, at a fraction of the usual cost.

Advantages Of MMES

Our unique CNC precision machining capabilities allows you to take advantage of speed, precision, size, cost and even volume. We deliver CNC machining services that allows you to machine parts in your desired material without compromising on cost, functionality and speed.

Scalability and repeatability.

Cost effective.

Speed and precision.

Locally owned and operated.

What Is CNC Machining?

CNC machining is a process that is used to create precise, complex parts and products.

CNC machining can be divided into two types: subtractive manufacturing and additive manufacturing. Subtractive manufacturing starts with an object and then cuts away material to create the desired shape. CNC milling is a type of subtractive manufacturing. It uses a rotating cutter to cut away material from the workpiece based on computer instructions. It can be used for many different materials like wood, metal, plastic, composites, etc., but it excels at cutting metals like steel or aluminium alloys.

In contrast, additive manufacturing builds up material layer by layer until it creates the desired shape from scratch. CNC routing is a type of additive manufacturing that uses a router bit to remove excess material in a specified path.

Reverse Engineering Services

3D Scanning Services

The first step in CNC machining is to create a 3D model on a computer of what you want to create. The program then converts this into instructions that are sent to the CNC milling machine. This process can take place in three different ways: by cutting, by turning or by milling.