Reverse Engineering brisbane

We recreate worn, obsolete, or undocumented components into accurate CAD models for maintenance, manufacturing, and production use. Our structured light 3D scanning delivers measurement accuracy up to ±0.04 mm, giving you engineering-grade geometry before CAD modelling.

Request a Reverse Engineering Quote

Upload photos, drawings, or measurements of the part. Including approximate size, weight, and intended use helps us quote accurately and quickly.

Fast Industrial Reverse Engineering When Time Matters

If a critical component failure threatens production or maintenance schedules, our structured workflow delivers precise CAD data and actionable results as quickly as possible.

Fast, Industrial-Focused Reverse Engineering

Rapid turnaround tailored to engineering and manufacturing needs.

Advanced Tools & Professional Team

We use professional-grade scanning equipment and CAD workflows designed for engineering and manufacturing applications.

Engineering-Grade Service

Trusted by manufacturers and maintenance teams for real part replacement and rebuild work.

Reverse Engineering Mechanical Parts to Keep Your Operations Running.

When a critical mechanical component breaks or is discontinued, production and maintenance schedules can grind to a halt. We help businesses get back to work quickly by capturing precise geometry and delivering usable CAD data for replacement, redesign or production.

We use structured light 3D scanning with measurement accuracy up to ±0.04 mm and professional CAD workflows to generate accurate digital geometry. This precision ensures confident reverse engineering and enables:

• recreate the part exactly

• modify or improve its design

• produce it via CNC machining or 3D printing as required.

Brisbane's #1 Reverse Engineering Firm

Trusted by Industrial Clients for Reliable Reverse Engineering

Our structured engineering workflow, precision tools and experienced team deliver accurate results consistently – supporting manufacturers and maintenance professionals in Brisbane and Southeast Queensland.

Advantages Of MMES

Our reverse engineering service delivers:

Accurate CAD geometry suitable for manufacturing and production

High precision and repeatability for engineered components

Efficient workflows designed for engineering and maintenance use

On-site scanning support when needed

Why Use Reverse Engineering?

Recreate parts when original CAD or drawings are not available

Support maintenance turnaround with usable engineering geometry

Prepare data for CNC machining or additive manufacturing

Verify critical features and ensure dimensional fidelity

Improve your product

Bring Your Parts into Modern Engineering Workflows

Our reverse engineering services deliver usable digital geometry for fault analysis, performance improvements, and reduced production risk.

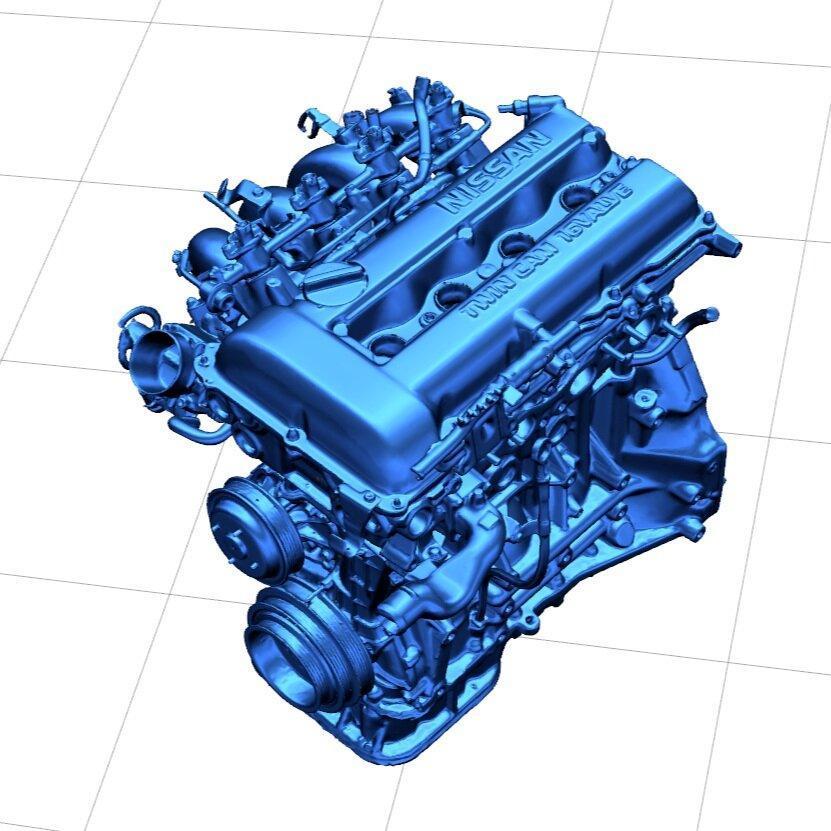

Reverse Engineering for Heavy Equipment and Industrial Vehicles

We support maintenance and engineering teams by recreating critical mechanical components used in industrial vehicles and machinery.

Typical work includes legacy components, wear parts, housings, brackets, mounts, and assemblies where drawings are unavailable.

If you require CAD-ready STEP models for manufacture or repair, upload photos and part details for a quote.

Reverse Engineering FAQs

What parts are suitable for reverse engineering?

We focus on mechanical and industrial components such as housings, brackets,

shafts, assemblies, tooling, and other engineered parts.

What accuracy can you achieve when reverse engineering parts?

We use structured light 3D scanning with measurement accuracy up to ±0.04 mm on suitable part sizes.

Final accuracy depends on part size, geometry, surface condition, and required tolerances.All scan data is verified and rebuilt into CAD before STEP delivery to ensure engineering-grade results.

Can you reverse engineer parts with tight tolerances?

Yes. For parts with critical fits or functional tolerances, we combine high-accuracy scanning with CAD verification and manual checks where required.

If a component has critical mating surfaces, let us know upfront so we can confirm suitability and approach.

What is the typical reverse engineering process?

We scan the physical component using structured light 3D scanning, process and verify the geometry, then rebuild it into a clean CAD model.

The final STEP file can be used directly for manufacturing, modification, or future documentation.

Do you need physical parts?

Not always — we can reverse engineer from a physical part using precision

3D scanning or from existing scan data/drawings when available.

What file formats do you deliver?

We typically deliver CAD-ready STEP (.stp) files suitable for CNC machining, fabrication, or 3D printing.

Other formats can be supplied on request depending on your workflow.

Can you produce manufacturing files?

Yes – we can prepare data suitable for CNC machining, prototyping, or additive

manufacturing.

How long does it take?

Turnaround varies by complexity, but quoting typically occurs within 1–3

business days once we have the part details.